AR Speeds Spacecraft Construction at NASA Goddard

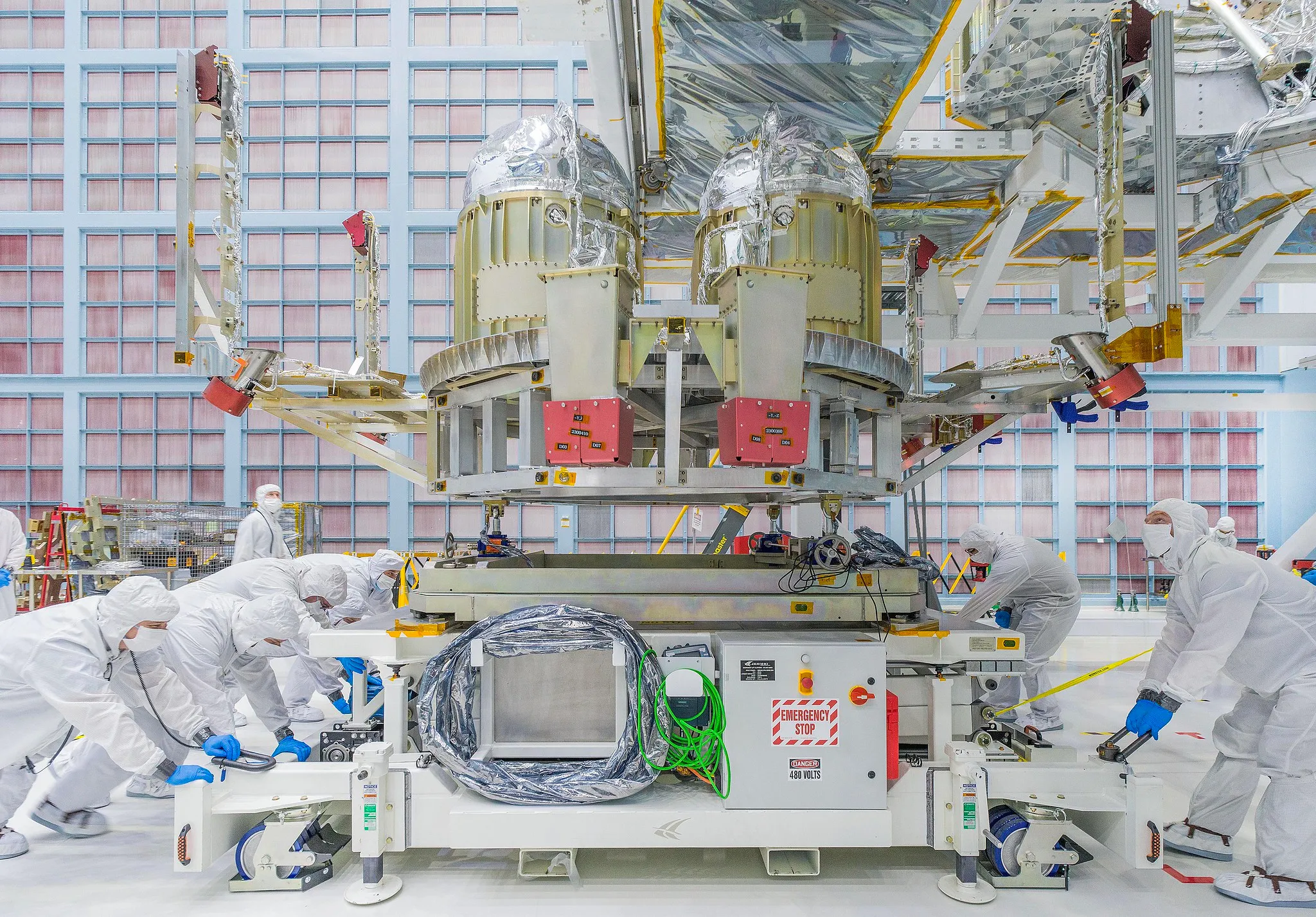

In this photograph from Feb. 29, 2024, at NASA’s Goddard Space Flight Center, the Roman Space Telescope’s propulsion system is positioned by engineers and technicians under the spacecraft bus. Engineers used augmented reality tools to prepare for the assembly.

Image courtesy of NASA/Chris Gunn.

BY: Karl B. Hille

Technicians armed with advanced measuring equipment, augmented reality (AR) headsets, and QR codes virtually checked the fit of some Roman Space Telescope structures before building or moving them through facilities at NASA’s Goddard Space Flight Center in Greenbelt, MD.

“We’ve been able to place sensors, mounting interfaces, and other spacecraft hardware in 3D space faster and more accurately than previous techniques,” said NASA Goddard engineer Ron Glenn. “That could be a huge benefit to any program’s cost and schedule.”

Projecting digital models onto the real world allows the technicians to align parts and look for potential interference among them. The AR heads-up display also enables precise positioning of flight hardware for assembly with accuracy down to thousandths of an inch.

Engineers wearing augmented reality headsets test the placement of a scaffolding design before it is built to ensure accurate fit in the largest clean room at NASA’s Goddard Space Flight Center in Greenbelt, MD.

Image courtesy of NASA.

Using NASA’s Internal Research and Development program, Glenn said his team keeps finding new ways to improve how NASA builds spacecraft with AR technology in a project aiding Roman’s construction at NASA Goddard.

Glenn said the team has achieved far more than they originally sought to prove. “The original project goal was to develop enhanced assembly solutions utilizing AR and find out if we could eliminate costly fabrication time,” he said. “We found the team could do so much more.”

For instance, engineers using a robotic arm for precision measuring and 3D laser scanning mapped Roman’s complex wiring harness and the volume within the spacecraft structure.

“Manipulating the virtual model of Roman’s propulsion assembly into that frame, we found places where it interfered with the existing wiring harness, team engineer Eric Brune said. “Adjusting the propulsion assembly before building it allowed the mission to avoid costly and time-consuming delays.”

Roman’s propulsion system was successfully integrated earlier this year.

Considering the time it takes to design, build, move, redesign, and rebuild, Brune added, their work saved many workdays by multiple engineers and technicians.

“We have identified many additional benefits to these combinations of technologies,” team engineer Aaron Sanford said. “Partners at other locations can collaborate directly through the technicians’ point of view. Using QR codes for metadata storage and document transfer adds another layer of efficiency, enabling quick access to relevant information right at your fingertips. Developing AR techniques for reverse engineering and advanced structures opens many possibilities such as training and documentation.”

The technologies allow 3D designs of parts and assemblies to be shared or virtually handed off from remote locations. They also enable dry runs of moving and installing structures as well as help capture precise measurements after parts are built to compare to their designs.

Adding a precision laser tracker to the mix can also eliminate the need to create elaborate physical templates to ensure components are accurately mounted in precise positions and orientations, Sanford said. Even details such as whether a technician can physically extend an arm inside a structure to turn a bolt or manipulate a part can be worked out in augmented reality before construction.

During construction, an engineer wearing a headset can reference vital information, like the torque specifications for individual bolts, using a hand gesture. In fact, the engineer could achieve this without having to pause and find the information on another device or in paper documents.

In the future, the team hopes to help integrate various components, conduct inspections, and document final construction. Sanford said, “it’s a cultural shift. It takes time to adopt these new tools.”

“It will help us rapidly produce spacecraft and instruments, saving weeks and potentially hundreds of thousands of dollars,” Glenn said. “That allows us to return resources to the agency to develop new missions.”

This project is part of NASA’s Center Innovation Fund portfolio for fiscal year 2024 at Goddard. The Center Innovation Fund, within the agency’s Space Technology Mission Directorate, stimulates and encourages creativity and innovation at NASA centers while addressing the technology needs of NASA and the nation.

To learn more, visit nasa.gov/center-innovation-fund.

About the author: With over 14 years at NASA Goddard, Karl B. Hille’s tenure has been marked by a commitment to distilling complex scientific concepts into compelling narratives that resonate with the public. As a communications lead and an editor, he focused on leveraging digital platforms to amplify our groundbreaking Tech R&D supporting NASA’s science and exploration missions. From spearheading the CuttingEdge quarterly to development and implementation of digital-first strategic communications plans, he excels at translating the future of space exploration for today’s audiences.

Mentorship has been a cornerstone of his professional journey, guiding interns through the intricacies of science communication and launching dozens of careers through patient counseling, providing resources, and removing obstacles to success.

The Goddard communication team’s collaborative efforts have consistently produced award-winning content that captures the imagination of audiences worldwide. With a deep-seated belief in the power of effective and strategic communication, Hille’s mission is to ensure that the awe-inspiring work at NASA Goddard continues to inspire and educate, bridging the gap between NASA’s science and engineering communities and the global public.

This article was originally published at https://www.nasa.gov/technology/goddard-tech/augmented-reality-speeds-spacecraft-construction-at-nasa-goddard/.